Tesla Coils can be and are very dangerous to one's health. If you decide to build one of these machines make all the safety precautions to ensure your personal safety.. The only reason for adding this information to the blog is to show you the readers that some of these alternative energy devices can be very dangerous to build.

Safety is always the most important factor when trying something new.

I found this site on how to build a tesla coil and decided to use it as an example of the amount of electrical power that this coil can create DeepFriedNeon - Tesla Coils

The question I have is what can it do for us? I can run lights but can't run our appliances in our homes. Even though this produces mass amounts of power it does not seem to be all that practical as a alternative energy device in its present state. Take a look at the following article, check out the website then make up your own mind as to how this device could become a practical alternative energy device.

What

is a Tesla Coil?

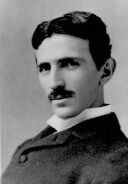

The

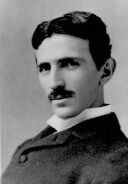

'Tesla Coil' is a device invented by the brilliant scientist Nikola

Tesla (born 1856, died1943). It is a high voltage, high frequency,

power generator, primarily built for conducting experiments and

to observe phenomenon associated with alternating electricity.

With this coil, Tesla was able to generate voltages of such magnitude,

they would shoot out of the apparatus as bolts of lightning!

Although

the sight of writhing streamers of electricity jumping though

the air is certainly spectacular, to Tesla it represented energy

loss. On occasion, Tesla deliberately adjusted his equipment to

produce these visible outputs as a means of gauging the state

of tune of the system, and to provide some feedback for his experimentations.

Today,

Tesla Coils are built by amateurs all over the world for one reason

only, the thrill of making your very own Lightning!

The

'Tesla Coil' is a device invented by the brilliant scientist Nikola

Tesla (born 1856, died1943). It is a high voltage, high frequency,

power generator, primarily built for conducting experiments and

to observe phenomenon associated with alternating electricity.

With this coil, Tesla was able to generate voltages of such magnitude,

they would shoot out of the apparatus as bolts of lightning!

Although

the sight of writhing streamers of electricity jumping though

the air is certainly spectacular, to Tesla it represented energy

loss. On occasion, Tesla deliberately adjusted his equipment to

produce these visible outputs as a means of gauging the state

of tune of the system, and to provide some feedback for his experimentations.

Today,

Tesla Coils are built by amateurs all over the world for one reason

only, the thrill of making your very own Lightning!

So

you want to build a Tesla Coil!

Step

1 - Motivation

Step

1 - Motivation

Initially,

your sole reason for wanting to build a Tesla Coil is to see the

fantastic light show they produce. You've surfed the Internet

and seen that it's possible for anyone to build a coil, so you're

thinking that you want to give it a try.

Required

skills: Building a coil requires ability in many different areas

of engineering. You will need to work with wood, metal, plastics,

adhesives/sealants; use hand and power tools for cutting and drilling;

work with mains electricity, wiring, soldering; improvise and modify

stock items, perform simple mathematical calculations, plan your

coil around what components you can find/afford. And finally, the

most important requirement of all is Time! Lots of it!

Step

2 - Size Matters

Most

of what you will now read here will seem dull and far away from

the excitment of homemade lightning. You'll probably want to skip

it and start building straight away but if you do you will soon

find yourself with lots of questions and no answers. You really

do need a plan!

What

size coil are you going to build? If money is no object, you

can get hold of all the components you need for your coil, from

anywhere in the world, and build a really powerfull one, but there's

a little more to it than that.

How

big should your coil be? When I talk about size I could be referring

to the physical dimensions of the coil, how tall and wide it is,

or I could be talking about the power rating, how many watts of

electricity it will consume. You are probably initially only thinking

about the size of the sparks you want to produce, so as a rough

guide you can use the following equation to calculate an input

power figure for an approximate spark length:

Step

2 - Size Matters

Most

of what you will now read here will seem dull and far away from

the excitment of homemade lightning. You'll probably want to skip

it and start building straight away but if you do you will soon

find yourself with lots of questions and no answers. You really

do need a plan!

What

size coil are you going to build? If money is no object, you

can get hold of all the components you need for your coil, from

anywhere in the world, and build a really powerfull one, but there's

a little more to it than that.

How

big should your coil be? When I talk about size I could be referring

to the physical dimensions of the coil, how tall and wide it is,

or I could be talking about the power rating, how many watts of

electricity it will consume. You are probably initially only thinking

about the size of the sparks you want to produce, so as a rough

guide you can use the following equation to calculate an input

power figure for an approximate spark length:

-

P

= input power in watts

P

= input power in watts

- L

= spark length in inches

-

-

- Example:

For 50 inches of spark, the power required is 865 watts

Before

you get carried away, there is one rather important point you should

consider:-

Do

you have the space to power up your coil?

Here

in the UK, an average sized single garage has sufficient room for

a Tesla Coil around the 1kW power level. The output streamers will

be cut short by the walls and ceiling but not too much.

You

may be tempted to build a really big coil and run lt outdoors.

It would be much more impressive and more people could watch it

at the same time, without having to crowd into a small garage,

but be warned! Pictures on a web site do not convey the real impact

a coil makes.

You

may be tempted to build a really big coil and run lt outdoors.

It would be much more impressive and more people could watch it

at the same time, without having to crowd into a small garage,

but be warned! Pictures on a web site do not convey the real impact

a coil makes.

Tesla

Coils are VERY VERY LOUD!!!

Don't

build a coil capable of 7 foot long sparks and run it in the garden,

only to find the neighbours get upset and call the Police!

Step

3 - Finding the Parts

Step

3 - Finding the Parts

Power

Transformer:

The

hardest component to get is the power transformer, and the range

of available High Voltage transformers is small. A

suitable voltage is from 6kV to 15kV(RMS).

Neon

Sign Transformer

Pole

Pig

20 KG

200KG !!

The

ultimate transformer is a 'Pole Pig' but it is not easy to get

one, and there are problems associated with transportation! For

the average person, the only possibilities are OBITs (Oil-fired

Boiler Ignition Transformers) and NSTs.

Check

out your local (and national) telephone directory for businesses

that deal in oil fired central heating or neon signs.

You

may have decided on the size of spark you want but the real limit

to your output is the transformer you manage to find.

Secondary

Coil Wire:

It

is recommended that you wind the secondary coil with one continuous

piece of wire. Small quantities of enameled copper wire are readily

available from hobbyist electronic component shops and mail-order

firms. Reel sizes vary from 50 grams to 500 grams, which is fine

for small coils but you will not have enough to make a medium

sized one.

You

will need to find a local company that will either sell you wire

in the quanties you need or who know of a supplier that will (wire

tends to come on 20Kg reels!).

Capacitors:

The

recommend type of capacitor for the tank circuit is currently

the MMC (multi-mini-cap). It is easy to build, easy to transport,

relatively cheap to make and is an excellent performer.

The

individual capacitors that make up the MMC (and the associated

bleed resistors) are available from mail-order electronics companies.

The

Rest:

All

the other material are readily available from local DIY stores.

Step

3 - Design

Step

3 - Design

You

should start calculating the design parameters based on the power

rating of the transformer you are using.

Example:

If you had an NST rated at 10KVRMS@60mA then the power is

V x I = 10000 x 0.060 = 600Watts.

Secondary

Coil:

The

power rating of a coil relates directly to the size of the secondary

because as the spark length increases with power, you get damaging

strikes to the primary coil unless you make the secondary coil

taller.

(You

can add a strike rail to the primary coil to protect it but if

your secondary is just too short for the power rating then all

you will get is strike rail hits and few streamers into the air).

Tesla Coils can be and are very dangerous to one's health. If you decide to build one of these machines make all the safety precautions to ensure your personal safety.. The only reason for adding this information to the blog is to show you the readers that some of these alternative energy devices can be very dangerous to build.

Safety is always the most important factor when trying something new.

I found this site on how to build a tesla coil and decided to use it as an example of the amount of electrical power that this coil can create DeepFriedNeon - Tesla Coils

The question I have is what can it do for us? I can run lights but can't run our appliances in our homes. Even though this produces mass amounts of power it does not seem to be all that practical as a alternative energy device in its present state. Take a look at the following article, check out the website then make up your own mind as to how this device could become a practical alternative energy device.

What is a Tesla Coil?

The

'Tesla Coil' is a device invented by the brilliant scientist Nikola

Tesla (born 1856, died1943). It is a high voltage, high frequency,

power generator, primarily built for conducting experiments and

to observe phenomenon associated with alternating electricity.

With this coil, Tesla was able to generate voltages of such magnitude,

they would shoot out of the apparatus as bolts of lightning!

The

'Tesla Coil' is a device invented by the brilliant scientist Nikola

Tesla (born 1856, died1943). It is a high voltage, high frequency,

power generator, primarily built for conducting experiments and

to observe phenomenon associated with alternating electricity.

With this coil, Tesla was able to generate voltages of such magnitude,

they would shoot out of the apparatus as bolts of lightning!

Although

the sight of writhing streamers of electricity jumping though

the air is certainly spectacular, to Tesla it represented energy

loss. On occasion, Tesla deliberately adjusted his equipment to

produce these visible outputs as a means of gauging the state

of tune of the system, and to provide some feedback for his experimentations.

Today,

Tesla Coils are built by amateurs all over the world for one reason

only, the thrill of making your very own Lightning!

So you want to build a Tesla Coil!

Initially, your sole reason for wanting to build a Tesla Coil is to see the fantastic light show they produce. You've surfed the Internet and seen that it's possible for anyone to build a coil, so you're thinking that you want to give it a try.

Most

of what you will now read here will seem dull and far away from

the excitment of homemade lightning. You'll probably want to skip

it and start building straight away but if you do you will soon

find yourself with lots of questions and no answers. You really

do need a plan!

What

size coil are you going to build? If money is no object, you

can get hold of all the components you need for your coil, from

anywhere in the world, and build a really powerfull one, but there's

a little more to it than that.

How

big should your coil be? When I talk about size I could be referring

to the physical dimensions of the coil, how tall and wide it is,

or I could be talking about the power rating, how many watts of

electricity it will consume. You are probably initially only thinking

about the size of the sparks you want to produce, so as a rough

guide you can use the following equation to calculate an input

power figure for an approximate spark length:

-

P

= input power in watts

P

= input power in watts

- L = spark length in inches

|

You

may be tempted to build a really big coil and run lt outdoors.

It would be much more impressive and more people could watch it

at the same time, without having to crowd into a small garage,

but be warned! Pictures on a web site do not convey the real impact

a coil makes.

You

may be tempted to build a really big coil and run lt outdoors.

It would be much more impressive and more people could watch it

at the same time, without having to crowd into a small garage,

but be warned! Pictures on a web site do not convey the real impact

a coil makes.

Power

Transformer:

The

hardest component to get is the power transformer, and the range

of available High Voltage transformers is small. A

suitable voltage is from 6kV to 15kV(RMS).|

|

|

|

|

|

|

|

Check out your local (and national) telephone directory for businesses that deal in oil fired central heating or neon signs.

You may have decided on the size of spark you want but the real limit to your output is the transformer you manage to find.

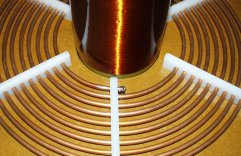

Secondary Coil Wire:

It is recommended that you wind the secondary coil with one continuous piece of wire. Small quantities of enameled copper wire are readily available from hobbyist electronic component shops and mail-order firms. Reel sizes vary from 50 grams to 500 grams, which is fine for small coils but you will not have enough to make a medium sized one.

You will need to find a local company that will either sell you wire in the quanties you need or who know of a supplier that will (wire tends to come on 20Kg reels!).

Capacitors:

The recommend type of capacitor for the tank circuit is currently the MMC (multi-mini-cap). It is easy to build, easy to transport, relatively cheap to make and is an excellent performer.

The individual capacitors that make up the MMC (and the associated bleed resistors) are available from mail-order electronics companies.

The Rest:

All the other material are readily available from local DIY stores.

| Example: If you had an NST rated at 10KVRMS@60mA then the power is V x I = 10000 x 0.060 = 600Watts. |

(You can add a strike rail to the primary coil to protect it but if your secondary is just too short for the power rating then all you will get is strike rail hits and few streamers into the air).

| Use this table as a rough guide to choosing the diameter of your secondary coil form. |

|

|||||||||||

| After lots of experimentation, the modern pioneers of Tesla Coiling have come up with the following rules for determining the optimum size of a secondary coil (see table). This gives you size of coil, so to get the form length add a couple of inches to the coil length. |

|

|

|||

Wire: Enameled copper wire comes in a wide range of diameters. You are aiming to have around 800 to 1000 turns of wire for your secondary coil so divide the coil length just worked out by say 900, to get the approximate wire thickness. The values manufacturers quote are for the copper conductor diameter. The enamel insulation usually makes the wire approx 10% thicker so allow for this in your sums. |

|

||

The coil has a characteristic inductance and capacitance which you will need to know. Feed the dimensions of your coil into the 'Helical Coil' calculator (see the 'Equations' section), using the 10% enamel width value for the turn spacing value.

|

|||

|

|

|||

Discharge Terminal: Discharge Terminal: |

|||

|

Now that the dimensions of the secondary coil have been determined you should think about the top load, or discharge terminal.

The classic shape is the

torus (ring doughnut shape) but anything without sharp corners will

work. The obvious alternative is a sphere.

Electrical Value: The discharge terminal acts as a capacitor and forms part of the secondary LC circuit. Its value is dependant on its shape and size, and can be worked out with the 'Top Load' Calculator. Calculate the capacitance of the top load and together with the calculated inductance (and self-capacitance) of the secondary, you can work out the resonant frequency for the secondary circuit (see below).

|

|||

|

|

||

Resonant Frequency of Secondary Circuit |

|

|

| We now have the two parameters needed to calculate the resonant frequency of the secondary circuit, namely the secondary inductance and the combined top-load and secondary capacitance. Use the 'LC Calculator' to work out this frequency. | ||

|

||

| Example: Following on from the examples above we feed in :- L = 21.82mH C = 10.5 + 16.6pF = 27.1pF or 0.0000271uF The resulting resonant frequency is 207KHz. |

||

|

|

|||

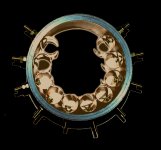

Primary Tank Capacitor: Primary Tank Capacitor: |

|||

| For

maximum output from your coil the value of the tank capacitor can be

calculated to match the transformer you are using. The spark gap fires

and transfers energy from the tank cap to the primary coil every

half-cycle of the mains supply (e.g. 100 times a second for 50Hz

supply). This means that the transformer only has the time in one

half-cycle (10mS) to recharge the capacitor for the next firing of the

gap. A capacitor that is only charged up to half its capacity in the

time allowed is not being used fully, and a small cap which could be

charged twice over in the time is missing out on half the power

available.

A

capacitor which is smaller or larger than this value will still work but

the power output will be less. Smaller is better than larger because

it's cheaper! Use the 'Cap Calculator' to find the matched value of capacitance for your transformer.

If

you decide on building an MMC style cap, use the 'MMC Calculator' to

work out the number of individual components you will need.

|

|||

Primary Coil: Primary Coil: |

|||

| The primary coil and the main tank capacitor form the primary resonant (LC) circuit. For proper operation, a Tesla Coil must have identical primary and secondary resonant frequencies. Using the 'LC Calculator' again, we feed in the value of our primary tank capacitor and then experiment with different values for L until we get a frequency match to the secondary circuit. | |||

|

|||

| Example:

Using the value of 0.031uF for our primary cap, we will aim to match

the resonant frequency of 207KHz (secondary circuit) by trying different

values for 'L' in the 'LC Calculator'.

With a value of L = 0.03mH we get a res freq of 165KHz, which is too low, and with L = 0.01, F = 286KHz, too high. With a little playing we find that we get a good match with L = 0.019mH. |

|||

| Having calculated the required inductance, you now need to decide on the actual physical parameters of the primary coil. |

|

||

For

a flat spiral coil, which is the prefered choice, you need to know the

width and spacing of the conductor, the diameter of the inner turn and

the number of turns to be able to find its inductance value. Use the

'Spiral Coil Calculator' to find a match for your target inductance.

Spark Gap: Spark Gap: |

|||

| The Spark Gap is the power switch for the primary tank circuit. It uses the air to conduct electricity between its electrodes and generates a great deal of heat in the process. | |||

| The size of the total gap is dependant on the supply, the higher the voltage the larger the gap that can be used. The gap is usually split into lots of smaller gaps, all wired together in series. This is done for two reasons; 1) The more gaps you have the more power it can handle; 2) It is possible to vary the firing voltage of the gap by changing the number of electrodes that are in circuit (by moving the connecting wires). |

|

||

| Individual

gap spacing of 20 to 30 thou (thousandth of an inch), 0.5 to 0.75mm,

with the total gap being around 6mm for a 10kV supply is roughly the

sort of dimensions you need, but it's not critical. If the total gap is

too big then the supply will not be able to break down the air and fire

the gap properly, and if it is too small then it will still work but at

less than optimum performance.

The

type of material and the size of the electrodes will affect the time the

coil can be run before the gap gets too hot and vapourises itself.

Copper requires regular cleaning to maintain maximum performance whereas

tungsten would not. Cooling can be added to help, in the form of a fan or blower. Vacuum cleaners are a favourite choice for coilers. The complete description can be seen a DeepFriedNeon Coils if you want to build your own unit. The importance of Tesla Coil I feel has been under rated. There is little doubt that this type of coil can produce enormous amounts of high frequency electricity but we do not need this high voltage high frequency to power our electrical appliances. There is danger involved in one way or another every time anyone tries to build an alternative energy device. The power that one house hold uses is substantial so when you look at the amount of electrical current required to supply all that power well all I can say is be careful. I am not trying to say not to build your own alternative energy device as this technology is in its infancy and there are many ways that people can adapt existing as well as new technologies to supply their energy requirements. | |||

Finding an economical, reliable alternative energy source will be the answer to the fossil fuel energy problems that we are encountering today.

If this blog just gets a few of you thinking and doing some experiments of your own then I have accomplished all that I have set out to do. Until the next blog

No comments:

Post a Comment

Please leave a comment.